- COMPANY

- PRODUCT

- TECHNICAL SERVICE

Engineering Solutions

Design the perfect system that meets your needs

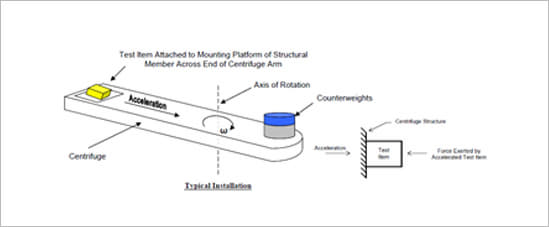

Test system that meets international test standards such as MIL-STD-810G 513.6, DO-160G and others for product acceleration environment criteria.

| Max. Acceleration (g) | 100 |

|---|---|

| Max. Payload (kg) | 150 (Including fixture) |

| Arm Gyration Radius (mm) | 1,500 |

| Table Size (mm) | 800 X 800 |

* Various specifications are available

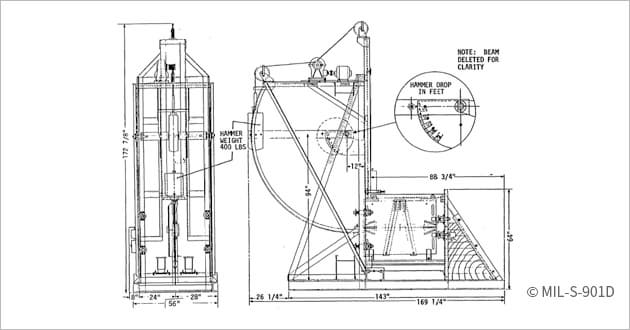

Test system that meets MIL-S-901D, including high impact environment test conditions for marine machinery and systems.

| Hammer weight (lbs) | 400 |

|---|---|

| Dimension (inch) | 169 ¼” x 56” x 172 7/8” |

| Fixtures | 4A, 4C, 6D-1&2, 6E, 11C |

* Compliance with MIL-S-901D

Test system that meets ASTM D2444, a standard for determining impact resistance of thermoplastic

pipe and fittings by means of a Tup.

Tup Weight is 900g, minimum drop height is 0.6 m, and maximum drop height is 2.3 m.

| Drop height (mm) | 2,300 |

|---|---|

| Size (W x D x H, mm) | 500 x 500 x 2500 |

| Drop / Release Method | Electric drop & release |

| Drop hammer | 900g 3types |

| Force Indicator | Measurement peak force by load-cell |

| Measurement accuracy | Within 3% |

| Rbound catcher system | Electric magnetic holder type |

Test system to conduct surface abrasion reliability test by means of test pen. Used by major Korean display manufacturers.

| Test Pen Size (mm) | Ø 8 ~ 23, Length 100 ~ 150 |

|---|---|

| Test Specimen Mounting Area (W x D, mm) |

400 X 500 |

| Test Type | * Tracing test - Zig-zag horizontal type - Zig-zag vertical type - Spiral type - Other patterns available * Tapping test - Continuous or non-recurrent tapping test - Repetition Speed: 2 per second |